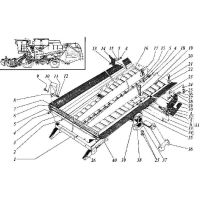

Cleaning

Parts cleaning for harvester DON-1500

Shock absorbers, bolts, shafts, bushings, hydraulic cylinders, combs, wheels, board, stars, keys, covers, drive shafts, housings, krylachi, covers, blades, flywheels, extension, suspension, bearings, sieves, levers, machines, hubs, extensions, clamps, gears, pulleys...

Parts cleaning harvester DON-1500

Purification harvester includes transport board mill with an upper extension and the upper sieve and the lower mill with a sieve bottom, a fan and drive mechanism. Grain and small heap, penetrated into the concave gaps, and finger-louvres walkers fall on the transport board, which sends mass in the upper sieve. It is bonded to the top. sieve box. Her before hanging on hangers on a frame grind. On the surface of the board mounted comb which divide the board into 4 parts. Combs make it impossible to shift to one side heaps TD in the transverse inclination of the combine

The top reshotny camp -. It is the continuation of the transport board. Connected with the board axis located at the top of the head arm, the rear edge is placed using 2-suspensions. Lower sieve pan is a box and pallet. Before the lower sieve box is suspended through the sleeve to the lower head arm and the rear part -. Through rubber bushings at suspension

and TD reshetnyh oscillatory motion is obtained by connecting rods, which are fastened with dvuplechnymi levers. On the sieve box set upper and lower louver sieves. Rotating flywheel, and shift rail is the opening/closing of the shutters. Tilt control shutters probe measuring the gap between the shutters through a hatch at the left side of the thresher. The upper louvre sieve required for separating large pieces heap.

Reshotny lower sieve mill varies in the reverse direction at a reduced amplitude as compared with the transport board and the upper sieve box. Inspection and cleaning sieves is carried out through the windows in the sides of the housing.

Under the influence of fluctuations in the TD pile stratified and then enters the lattice on the finger, where large impurities remain, and the fines fall into the top of the upper sieve. The coarse fraction, which is supported by the air flow, falls to the middle finger on the sieve lattice. Before unloading the upper sieve cleaning, toe grille provides uniform loading of the sieve. Therefore, the bulk of grains and small impurities screened in the beginning of the upper and then the lower sieves. At the same time loosening the air stream blowing the heap and all light particles directed to polovonabivatelyu. Clean grain is sent to the bottom dec. mill and then use the elevator and dispensing auger enters the hopper.

At the end of the upper sieve and caught on extended tailings, falling through between the plates and fall within the auger housing. Neobmolotye spikelets elevator sent to regrinding. device and there is threshed dumping a pile in the auger. Screw grain heap was partitioned across the cleaning width. Screw conveyor shaft is welded to the helical ribbon. Downstairs in the screw too rassmezheny sewage hatches.