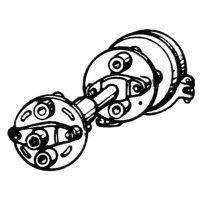

Transmission cardan

Spare parts for the driveline tractor DT-75

The shafts, plugs, bushings, nuts, head pads, levers, flanges, pulleys, sheaves, forks...

Parts driveline to the tractor DT-75

It is necessary for the transmission of the rotation from the HMS to the UKM and their relative compensation of inaccuracies. Front fork driveline is fitted on shaft splines GMR rear fork on a leading-slots. shaft. Plugs are mounted on shafts and Port. with the heads of the cardan. To the head gimbal attached to the leading and trailing plugs.

The head gimbal includes two discs with 4 cylindrical sockets and vpressovanymi them with rubber bushings. They are fastened by means of rivets 4 and spot welding. Rubber plugs made of frost-resistant rubber are in the closed position in the nests of discs. To increase the strength of their outside reinforce rubberized cloth and inserted inside the cylinder and privulkaniziruyut. frames of metal mesh. The rubber bushings themselves pressed into steel sleeves, two on each side of the head. Projecting cylindrical sleeve belts come into flange openings facing crosswise forks.

Middle Fork, the master and remote bonded with each other by means of splines and can mutually move in the axial direction. Therefore it is possible to change the length of the driveline necessary to compensate for inaccuracies in assembling the engine and the transmission in the longitudinal direction. Misalignment and shaft misalignments HMS and UKM are compensated by the elasticity of the rubber bushings cardan heads.

Flanges and middle forks arranged crosswise thereby contributing to improved compensation errors. Cardan little can compensate for inaccuracies, so the engine is put so that misalignment and skew HMS shaft and drive shaft UKM were no more than 2 mm. Leading and driven fork are hollow cavities closed on one side by stamped plugs which prevent the spline forks from moisture and dust. With tormozka after disconnection GMR stopped MSN and primary Transmission shaft for their unstressed inclusion.

tormozok driveline DT-75

When switching GMR tormozka lever fork roll off GMR rotated clockwise direction and acts on the stop bolt. He and the brake pad climb, picking gap and a pulley lining. When the HMS will be completely turned off, the brake pad is pressed against the spring through the pulley, and this inhibited driven power transmission parts. In this case, by additional. compression springs between the abutment shoulder and arm bore a gap of 45 mm, the required shims to compensate for brake pad wear. With these clearances wear lining are reduced. When the focus moves away from the HMS bolt and tormozka block by a spring is removed from the pulley.