Brakes ZIL

Spare parts for brake system Zil

cylinders, drums, bushings, cylinders, diaphragms, brake discs, brake pads brakes, fists, oil separators, covers, supports, pistons, spring, repair kits, calipers, ratchet, hoses...

Spare parts for brakes for ZIL

Brakes ZIL 130

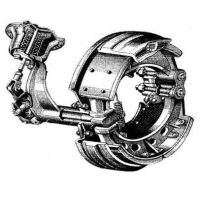

Based on the pneumatic actuator. The compressor during operation of the engine injects air into the cylinders. On pressing the brake pedal, the brake valve through the air directed to the rear and front chambers arranged next to the corresponding wheels. The camera aperture is set. It tends to sag with increasing pressure and thereby actuates the levers to the stem. The consequence of this is cranked shaft with expander lock, and then move apart pads that press them to the brake drum

Brake Pads -. Cast iron, plate occurs by a spring supported them lower ends on eccentric fingers and upper - on the expansion fist. Pads are supplied with 2 friction linings. In order to avoid lateral displacement pads keep their grip clad fingers at the other end of the bracket, covering garter spring. Expansible produce fist shaft. At the outer end (with slots) worth lever inside the cat-th stands with a worm gear. Rod lever is connected to a diaphragm sandwiched between the lid and the brake chamber housing.

The compressor needs to maintain a constant supply of compressed air. For this and give piston compressor with 2 cylinders on the cylinder head, and is driven via a belt pulley of the cooling fan. It includes a housing, a rocker arm 2 inlet and 2 injection valve, connecting rods, crankshaft, cylinder head, a plunger 2, pistons, drive pulley 2 and the rod. Due to the vacuum, which is created by the compressor, the piston goes down and the delivery valve moves to the closed position. Following the inlet valve opens and the compressor via the pipe in the cylinder falls purified air filter. When the piston moves upwardly, closing the intake valve occurs, air is compressed in the cylinder and its pressure opens the delivery valve, through which air gets into the head chamber. The head is cooled by the water method.

Air cylinders give 8-10 completions without braking compressed air supply by a compressor. Fixed to the longitudinal beams of the frame. They have air lines which supply compressed air to the brake valve and spout adjoint air duct that comes from the compressor. At the bottom of the tank should drain cock condensate formed during the injection of compressed air into the cylinders. In order to avoid damage caused by excessive pressure in the right cylinder pose a safety valve. It opens in an automatic manner when the pressure increases in the amount of 9.0 -. 9.5 kg/cm2

Brake valve is formed with rubber flaps and elastic conical diaphragm of rubberized fabric. The diaphragm is clamped between the lid and the body of the crane, and it is connected with the guiding glass. On the axis of the housing should brake valve lever. In case there is a valve which closes the discharge hole and the spring together with the glass. The exhaust and intake valves are provided with return springs.

When the wheels are in the braked state, a conical exhaust valve is open and the internal cavity is connected to the brake chambers of the brake valve cavity. And in turn sogpryagaetsya cavity with the atmosphere, and a conical inlet valve due to the pressure of the spring closed. Brake pedal is lowered and joined to it displaces the thrust lever of the brake valve. He in turn clamps the saddle, balanced by a spring to the outlet valve. The rod connecting valves, opens the inlet. As a result, brake chambers are filled with compressed air, and the wheels are braked.

Spare parts and details brake ZIL wholesale and retail online store of spare parts for tractors, combines, construction machinery Motor-Agro ✈ Shipping to any city in Ukraine ☎ call